Ribbed support vaults for 3D printing of hollowed objects

Thibault Tricard, Frédéric Claux, Sylvain Lefebvre

Computer Graphics Forum

HAL

DOI

Abstract

Additive manufacturing techniques form an object by accumulating layers of material on top of one another. Each layer has to be

supported by the one below for the fabrication process to succeed. To reduce print time and material usage, especially in the

context of prototyping, it is often desirable to fabricate hollow objects. This exacerbates the requirement of support between

consecutive layers: standard hollowing produces surfaces in overhang that cannot be directly fabricated anymore. Therefore,

these surfaces require internal support structures. These are similar to external supports for overhangs, with the key difference

that internal supports remain invisible within the object after fabrication.

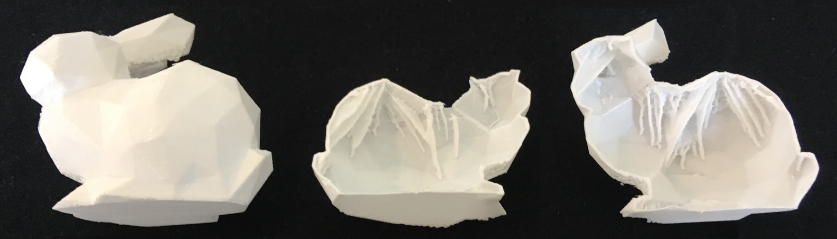

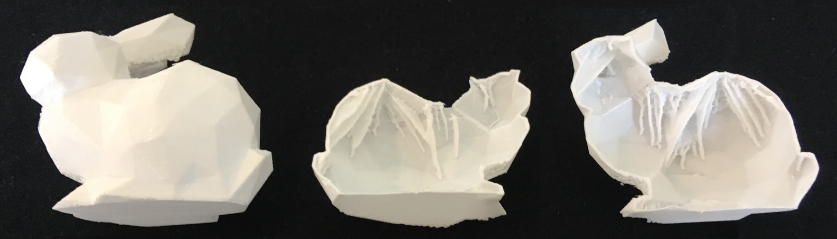

A fundamental challenge is to generate structures that provide a dense support while using little material. In this paper, we

propose a novel type of support inspired by rib structures. Our approach guarantees that any point in a layer is supported by

a point below, within a given threshold distance. Despite providing strong guarantees for printability, our supports remain

lightweight and reliable to print.

We propose a greedy support generation algorithm that creates compact hierarchies of rib-like walls. The walls are progressively

eroded away and straightened, eventually merging with the interior object walls. We demonstrate our technique on a variety of

models and provide performance figures in the context of Fused Filament Fabrication (FFF) 3D printing.